Compressed Air Oil Barrier

The compressed air oil barrier or compressed air barrier is a system that has been used for more than 50 years in locks, ports, rivers, canals, or to protect industrial plants. Rising air creates a barrier in the water and holds back everything that floats on the water. When used optimally, the compressed air oil barrier primarily prevents the spread of oil and floating debris.

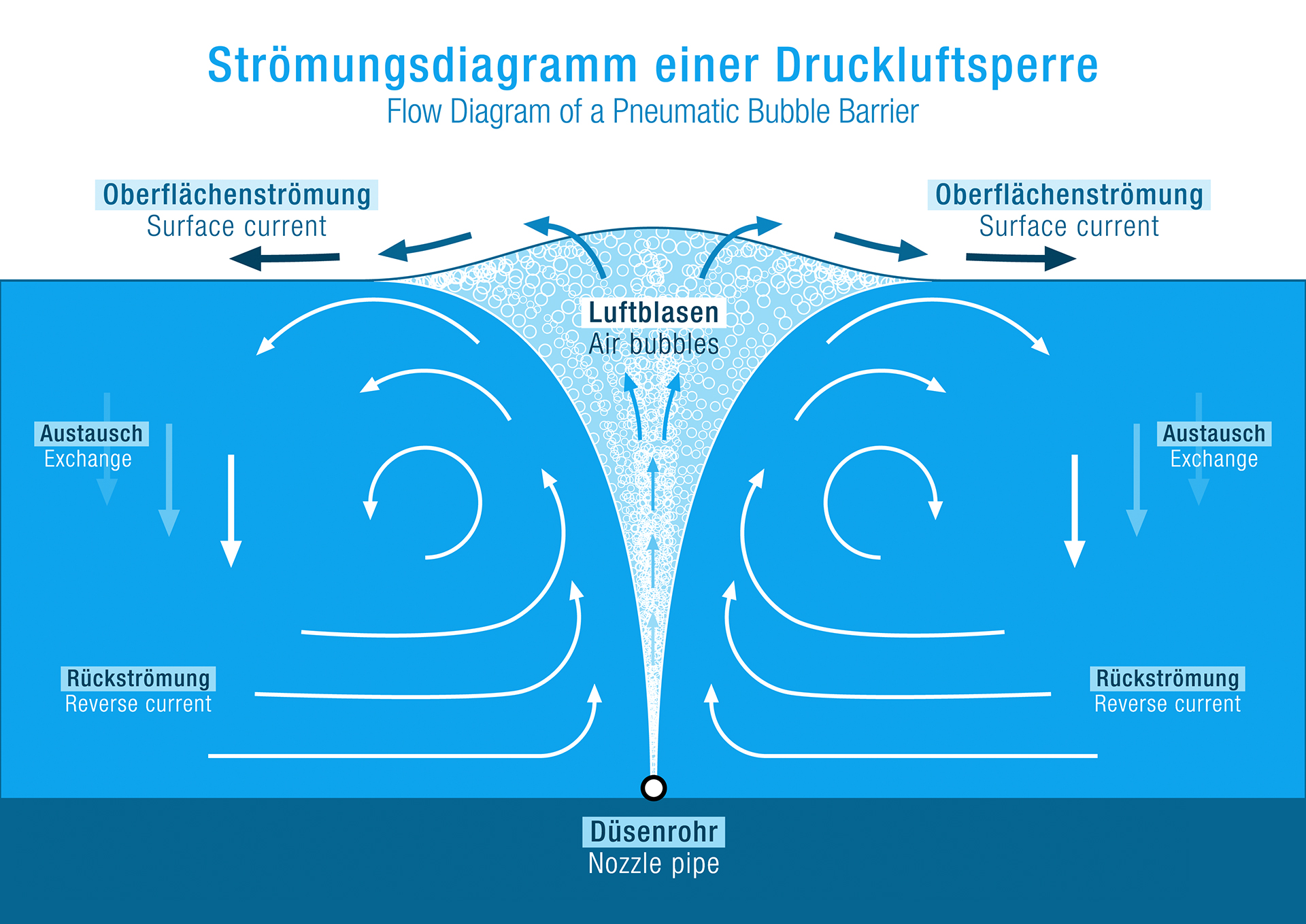

Compressed air oil barrier creates 2 horizontal currents

In a permanently installed system, hoses or pipes are anchored to the water’s bottom with special nozzle openings. When used, the compressed air generated in a compressed air station is pressed into the nozzle tube. The air emerging from the nozzles creates a vertical current in the water, converted into two horizontal currents on the water’s surface. These horizontal currents hold back oil and other floating matter floating on the surface of the water. Boats or ships can pass the barrier unhindered. A permanently installed compressed air oil barrier is usually ready for use in a few minutes after activation. It can be operated without additional labor and can also be used in the event of a fire.

Skim off permanently

The effectiveness of a compressed air oil barrier is exhausted when the pressure on the barrier increases and the force of the flow exceeds the force of the flow due to the steadily running oil or rising debris. In the event of an emergency, the floating substances must be skimmed off simultaneously to maintain the barrier’s function.

For this, we provide the necessary equipment or produce it for the current requirement. We provide skimmers to skim off oil from the water surface or floating barriers to hold back oil or floating debris. We also manufacture specially equipped boats. To store the critical substances, you will receive appropriate tanks, set up quickly, and flexibly transported.

Compressed air oil barriers in use worldwide

We have been planning, building, and installing compressed air oil barriers for more than 50 years.