The first 3 foundations have rammed into the seabed and the Transition Pieces mounted. The phase of the offshore Wind Farm SeaMade founding has started.

Around 50 km off the Belgian coast, the largest Belgian offshore wind farm, the “Offshore Wind Farm SeaMade” is being built. With a capacity of 487 megawatts, it is expected to deliver renewable energy by the end of 2020 for approximately 500,000 households. For the installation of the 58 monopile foundations, DEME Offshore uses the jack-up vessel “Innovation”. For underwater noise control, the Master Express has been equipped with the Big Bubble Barrier System.

Every single hammer blow of the wind farm SeaMade founding generates massive noise

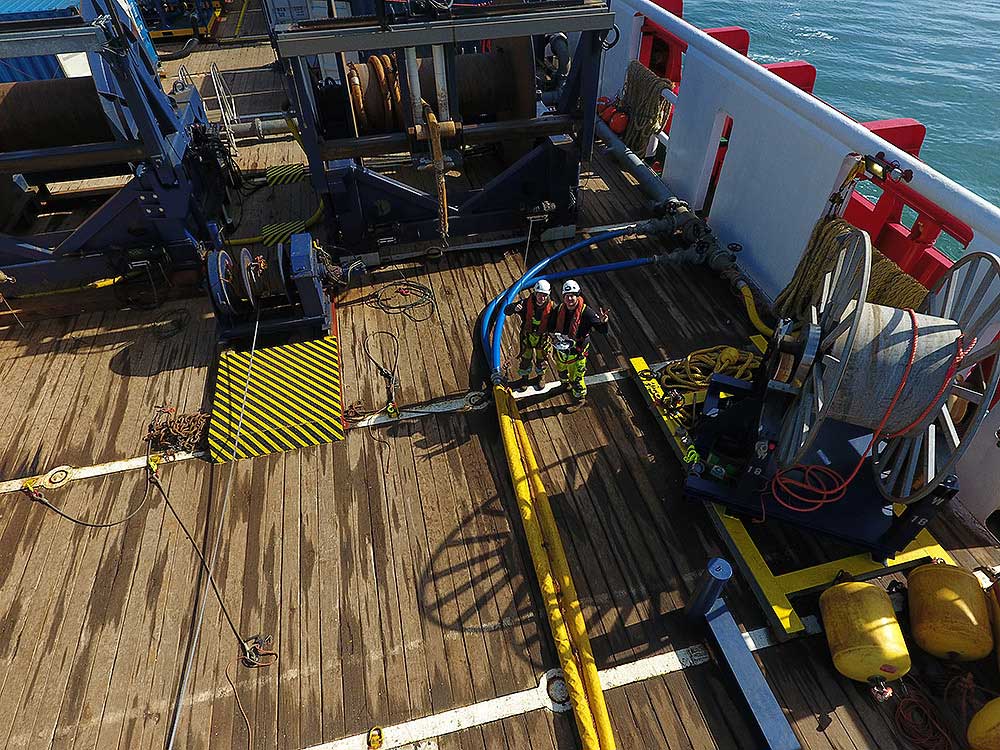

Bernd Kadereit and Chistian Wulf of the HYDROTECHNIK LÜBECK GMBH team are responsible for the installation and operation of the Big Bubble Barrier on board the Master Express. It ensures noise protection in the water using compressed air circumferentially placed around the respective ramming position.

Every single pile of impact generates massive noise in the water body. This is even life-threatening for sea dwellers even in the far distance and deadly in the immediate vicinity. The double-installed nozzle hose of the Big Bubble Barrier retains up to 95% of this noise.

For DEME Offshore, responsible for the construction and the Wind Farm SeaMade founding, this measure is important for protecting all marine life forms. Ecologically sensible electricity should not cause damage to nature even in the construction phase of a wind farm.