An article by Werner Evers, a freelance journalist

Hydrotechnik Lübeck reduces hydro noise and protects nature with the Big Bubble Curtain

Floating work platforms with gigantic crane systems are towed to the North Sea, work ships and helicopters commute back and forth. Eemshaven has become a huge material warehouse and base for something really big on the North Sea. The industrial port is strategically located on the Dutch side of the Ems estuary.

The federal government wants to phase out nuclear energy. By 2030, 5,000 wind turbines are expected to be rotating in the North and Baltic Seas. 60 nuclear power plants would no longer be necessary if these wind turbines generate 25,000 megawatts of electricity – a unique order for the German energy industry and an ambitious industry challenge.

Every wind turbine as big as Cologne Cathedral

On the North Sea, the wind blows strongly and steadily. It is ideally suited for the task of “electricity through the wind”. Huge areas in the middle of the North Sea have already been designated for these major construction sites. Far enough from land not to disturb the view of the water. But the sea is a sensitive ecosystem with many important living things that are worth protecting. So if gigantic wind turbines are erected there, nature must not suffer. Every wind turbine is as big as Cologne Cathedral.

Scientists and nature associations pointed out the extreme noise emissions in the water at an early stage. Harbor porpoises would die permanently at this level of underwater noise. For the foundation of just one wind turbine, up to 4 driven piles are driven into the seabed. Each post is 55 meters long and weighs about 200 tons. They are driven 40 meters into the ground with a pile hammer through mud and almost concrete-hard sand. Around 3,000 rams are required for this – for each pillar. Underwater noise protection is urgently needed.

The engineers at HYDROTECHNIK from Lübeck have taken on this task. After 2 years of research and development, a system is now ready for use. The “Large Bubble Veil HY75”. At first, the idea was as simple as it was simple. Air bubbles change the density of the water; the sound is broken and not transported further. However, the demands on this new technology were high. Crucial reference values had to be achieved, and the rapid construction speed could not be disturbed. 5 million euros were used to achieve a workable result. The funds came mainly from the Federal Ministry for the Environment. With technical support from the University of Hanover and the expertise of BioConsult and ITAP, it is now done. The “BIG BUBBLE CURTAIN HY75” system is ready for use.

The engineers at HYDROTECHNIK from Lübeck have taken on this task. After 2 years of research and development, a system is now ready for use. The “Large Bubble Veil HY75”. At first, the idea was as simple as it was simple. Air bubbles change the density of the water; the sound is broken and not transported further. However, the demands on this new technology were high. Crucial reference values had to be achieved, and the rapid construction speed could not be disturbed. 5 million euros were used to achieve a workable result. The funds came mainly from the Federal Ministry for the Environment. With technical support from the University of Hanover and the expertise of BioConsult and ITAP, it is now done. The “BIG BUBBLE CURTAIN HY75” system is ready for use.

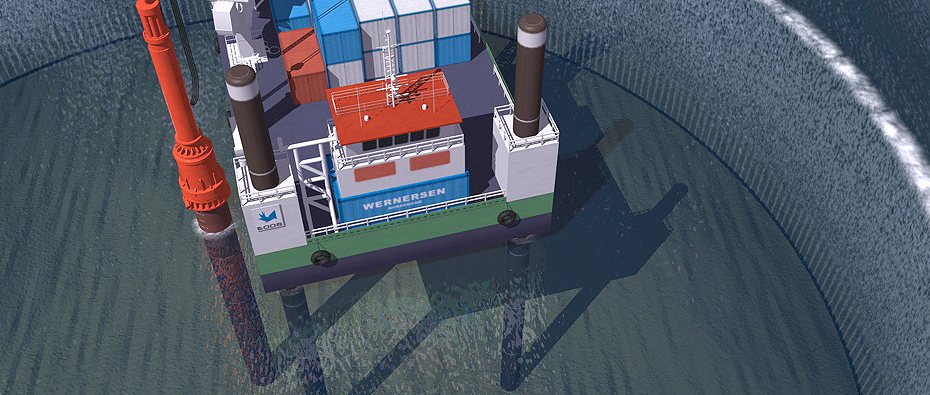

How it works is simply explained. A special ship, the NOORTRUCK, is equipped with 3 large hose winches and a cluster of powerful compressors. Before the ramming platform takes its position, the NOORTRUCK has already sunk a hose ring in the North Sea. Exactly circular around the construction site, with a diameter of around 160 meters. The hose ends are fixed to the water surface by buoys. Now the platform can be towed up because the NOORTRUCK is already sinking another hose into the next position. The advantage: the platform can carry out its preparations for the pile driving work undisturbed. Shortly before the pile hammer begins, the NOORTRUCK docks onto the hose end. The compressors are started up, and a soundproof fence made of air bubbles is created around the construction site. Once all the piles are stuck deep in the seabed, the dismantling of the platform begins. The NOORTRUCK uses this time to sink the next hose into another position. While the platform is in its new position, the first hose is recovered from the seabed.

Cay Grunau, graduate engineer and managing director of HYDROTECHNIK LÜBECK GMBH

“The bubble curtain used in the Borkum West II project more than fulfilled the expectations placed on it. Spreading, operation, and recovery work smoothly. Of course, we expected a noise reduction. However, the first measured values are between 152 and 158 dB, which corresponds to a reduction in the sound level of up to 15 dB. That surprised us all. We are even below the limit set by the authorities. Now we are working on optimizing this value ourselves. It should be possible to improve the reduction by a factor of 2 by changing the design and routing of the hoses. ”

Know-how, competence, and extraordinary specialist knowledge have grown at HYDROTECHNIK Lübeck for 30 years. The openness to work in a competence network allows you to develop yourself further. For the Cay Grunau team, teamwork is the top priority when it comes to protecting the seas. So they can contribute to something really big.

Mr. Grunau, where did the first impulse to develop the ‘Big Bubble Curtain’ come from?

HYDROTECHNIK LÜBECK has been dealing with compressed air in hydraulic engineering for more than 30 years. We have installed so-called compressed air oil barriers to protect against oil pollution in many tanker ports worldwide. In the case of application, the harbor entrance is usually blocked within minutes by this bubble curtain. The flow of rising bubbles holds back the oil. We have built the largest plants to date in Italy, Croatia, and the United Emirates. With these systems, we came up with hose lengths of 1000 to 1500m. They were laid in water depths of 60 m.

The initial spark for developing the bubble curtain for offshore underwater noise protection came from the FINO 3 project. As part of this project, noise protection for pile-driving work on a monopile in a water depth of approx. 24m had to be designed, built, and operated within 6 weeks. Only we as a specialist company was considered for this task. We had already had an outstanding experience in noise protection when detonating ammunition in the Baltic Sea. As a result of a worldwide environmental protection campaign by NABU Schleswig-Holstein, awareness of underwater noise protection arose during this work. We got the chance to develop this technology. As with any other project, we approached FINO 3 with confidence. We tested materials again and then ultimately developed today’s functioning system through trials.

There is evident uncertainty in the press about the impact of underwater currents on results. The ‘large bubble veil’ is said to be affected. At Wikipedia, you can read it is the Small bubble veil ’. How is your experience there?

The prevailing water currents are the most important factor to consider for the effectiveness of the bubble curtain. If the bubble curtain is designed correctly, the average flow velocities occurring in the North Sea do not impair its effectiveness.

For this task, you are working with a special ship, the ‘NOORTRUCK’. What can this ship do, and how is it equipped?

A requirement for the conversion of this ship was the size. The NOORTRUCK is big enough to carry the equipment for 3 bubble curtains. Also, the ship has sufficient space for the compressors required. The second characteristic, which is no less important, is the maneuverability of the ship. This is very important for laying the hose rings. And ultimately, the NOORTRUCK is a ship on which the crew can feel comfortable.

Why is the ‘HY75 ′ system now equipped for continuous use?

As part of the testing and daily use in the Borkum West II construction area, we could eliminate the last “teething troubles”. Any new system is usually developed enough to work. However, it takes daily effort to identify and fix “squeaky” spots. Usually, it was small changes that make it easier to use daily.

Mr. Grunau, the sea and shipping seem to be your passions. Nevertheless, you became a civil engineer, why? And how did nature conservation come about?

I am a civil engineer in the hydraulic engineering department by conviction. This has been clear to me since I was allowed to accompany my father to a construction site in the Sauerland on the Ennepetalsperre at the age of 12. Nature is just too beautiful and important to us. So you have to protect it where it is in danger. Is there anything better than being active on and underwater and at the same time protecting part of the animal world? Except for the smiles of my wife and children.

Up to 5,000 wind turbines are to be built in the North and Baltic Seas. Are there other companies that have your know-how?

Not at the moment, but they will undoubtedly arise given the expected market potential.